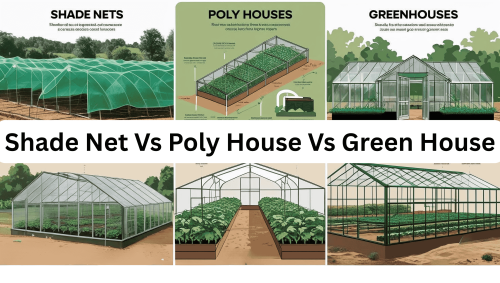

Are you going to start your horticulture adventure? It will require substantial investment, time, and thorough analysis before proceeding. Various factors affect the crops and plants, and the selection of structure for CEA (Controlled Environment Agriculture) requires full attention. If you want the best agricultural structures for crop protection, our simple guide will help you. All you need to do is read this comparison, as everything you require is included within it. What is Controlled Environment Agriculture? In horticulture, a controlled environment is used to get the desired results. For that objective, a completely covered structure is used to provide the optimum temperature, light, humidity, carbon dioxide, and pest control. Therefore, it is called CEA (Controlled Environment Agriculture). These structures require materials that can help achieve the best results. People who want to create this setup often want to know the shade net vs polyhouse vs greenhouse comparison. People who practice organic farming also need to know what suits them best in this approach. Here is a detailed comparison to help you decide what’s best for you. Shade Nets Shade Nets are PE nets that help to provide shade for various reasons. Not only for plants but also for general shading, these nets do a great job. What makes them completely different from a polyhouse and greenhouse is their structure. They are available in either knitted or woven form, making them suitable for providing shade. Moreover, the shading percentage varies from 30% to 90%. Main Features • It is the best choice to protect anything from UV rays. The higher the shading percentage, the higher the UV protection will be. • It excels at providing ventilation, making it suitable for general installation in homes, pools, and gardens. • Its lightweight design makes it easy to install and replace. You can check out more details here. Pros and Cons • It is a low-cost solution in terms of shading. That means you can cover plants in a nursery from intense UV rays. • It also provides some level of pest protection if the plants are entirely covered with it. • However, it cannot protect against heavy rains and extreme heat besides providing ventilation. Additionally, they cannot resist heavy and prolonged snowfall. • After a few years, you will need to replace them with new ones due to their shorter lifespan. • Apart from crops, shade nets for home gardening & lawns are also helpful. Overall Cost It is the most cost-effective mode of shading compared to a polyhouse and a greenhouse. Its initial setup is simple and requires fewer laborers and equipment. Moreover, its maintenance and replacement are cheap. For more information, contact us. Ideal Application Shade nets are commonly used in nursery gardens and to shade leafy greens. Their primary objective is to shield the plants from direct sunlight, which could cause them to burn. On the other hand, air ventilation remains in place. Poly Houses Then the second one is a polyhouse. It is an advanced version of CEA, and it is based on a galvanized steel structure and PE films. It is one of the most popular and cost-effective farming solutions in horticulture. Polyhouses or polytunnels provide a semi-controlled environment. The sunlight, air, humidity, and temperature are different in it than shade nets. Even the pest resistance is better in it. Main Features • It can protect plants and farms from light to medium rain. • The ventilation system is better than the shade nets. • Even the temperature moderation is better in it. • Polyhouses provide better control against the growth of pests and diseases. Pros and Cons The cost is moderate as compared to shade nets and greenhouses. It is because the galvanized steel structure is more expensive than shade nets, but PE sheets are less costly than glass. The insulation level in polyhouses is limited, which can lead to failure in extremely hot weather. Additionally, heavy rains, blizzards, and snow can cause damage to polyhouses. Cost Analysis Its cost is higher than a shade net but lower than a greenhouse. The reason is that it requires laborers, a galvanized steel structure, and PE sheets. Additionally, the maintenance cost is higher than that of shade nets. Common Applications Polyhouses are suitable for small-scale farming or horticulture. Cucumber, tomato, chili, spinach, and cabbage are some vegetables that can be grown in a polyhouse. This CEA type is suitable for areas with moderate temperatures and weather. Heavy rains, snowfall, blizzards, and storms can damage them. Green Houses In this final stage, you will find out the main greenhouse vs. polyhouse differences. A greenhouse is the most advanced type of CEA for horticulture. Not only is it advanced, but it is also more expensive and durable. It boasts a durable structure made from glass and steel. Some people use polycarbonate panels, which are a slightly cost-effective solution. Main Features • A greenhouse provides complete climate control, regardless of whether it is raining, snowing, or the sun is baking everything. • It allows farmers to conduct general farming and also hydroponic farming. • It also features a ventilation system with fans to cool down the temperature during extreme heat. • A greenhouse gives you a fully controlled environment. Pros and Cons • A greenhouse provides a stable structure that protects plants from heavy rains, snow, blizzards, storms, and extreme heat. • Even the pest resistance level is the highest in this controlled CEA. • However, the upfront cost is the highest compared to other methods. The additional systems, like cooling fans and lighting systems, can increase the price. Cost Analysis According to the cost analysis, a greenhouse requires a significant initial investment. Also, its maintenance cost is higher because it requires energy to provide optimum results. Ideal Uses • People install greenhouses for commercial farming, organic horticulture, high-value fruits and vegetables, and botanical experiments. • It can adapt to all types of climates in various regions. Therefore, it can operate day and night for the customized production of plants. Comparison: Shade Net vs Polyhouse vs Greenhouse Let’s make it more precise to give you highlights of what we mentioned earlier. It will make things clearer for everyone. Cost Comparison The setup cost goes from the lowest to the highest, from shade nets to greenhouses. Shade nets are made of woven polyethylene, which is the most cost-effective material. At the same time, polyhouses require PE films and a galvanized steel structure, which makes them costlier than the previous option. However, greenhouses are the most expensive because they need glass or polycarbonate panels along with steel structures. Likewise, their maintenance costs also vary in the same manner. Durability and Lifespan The durability level also varies depending on the material strength and type of structure. Shade nets could last a maximum of five years or slightly more. A polyhouse’s PE films could last for hardly four years, depending on the weather conditions. However, their steel structure could last up to fifteen years or more. In contrast, a greenhouse has the highest durability in terms of panels and structure. Its panels could last over tens of years, as well as the structure. Even in harsh weather, a greenhouse can survive way longer than others. Climate Control Efficiency When it comes to climate control efficiency, shade nets have very little impact. In comparison, polyhouses provide better control of temperature, light, humidity, and pest control at a moderate level. In contrast, greenhouse climate control structures in agriculture are the best. They offer complete control over environmental elements for customized farming and botanical experiments. Crop Suitability If you are dealing with basic nurseries, plants, and leafy greens, shade nets are a good choice. If you want better results at a large scale for farming tomatoes, chillis, cabbage, etc., a poly house is a better choice. If you want a sustainable and customized solution in agriculture, a greenhouse is the best. You can grow different types of vegetables and crops for optimum results in a greenhouse. Scalability and Labor Requirements A shade net CEA requires little or no labor at all. It has better scalability because you can add more nets when needed. If it is about a poly house, you will need more laborers and equipment, and its expansion will also be challenging. In contrast, a greenhouse requires the highest number of laborers, equipment, and scalability costs. Expanding a greenhouse needs more investment and manpower. Environmental Impact Shade nets are the simplest and most cost-effective type of CEA. You will need no energy to maintain it, and it also has a smaller carbon footprint. Yes, frequently changing it increases the carbon footprint through plastic consumption. Polyhouses require no energy but have a plastic impact on the environment. The greenhouse requires energy for its cooling and lighting systems, which undoubtedly have an impact on the environment. However, the environmental and carbon footprint levels seem to be low because it does not require frequent replacement of its panels. Comparison Table Low and medium installation and maintenance costs Shade nets and then a polyhouse Best environmental protection A greenhouse and then a polyhouse Durability and longevity A greenhouse and then a polyhouse Pest control A greenhouse and then a polyhouse Good insulation level A greenhouse and then a polyhouse Best temperature control A greenhouse and then a polyhouse Highest crop productivity A greenhouse and then a polyhouse Lowest carbon footprint Shade nets and then a polyhouse Fully controlled environment A greenhouse Factors to Consider When Choosing a CEA There are some factors that every farmer or botanical expert should consider before choosing the CEA. Local Climate and Weather Conditions You must be aware of the local climate, including its weather conditions. If the weather is harsh, with frequent occurrences of heat, rain, storms, or snow, you should consider using a greenhouse. If the climate is mild, you can choose any CEA, depending on your objectives. Crop Type and Growth Requirements For optimal growth requirements, consider using a greenhouse. The installation and maintenance costs will be high, though. You can choose a poly house if the crops meet the conditions. Budget and ROI Expectations If it is a short-term project, shade nets or a polyhouse are good options. If it is a long-term project, a greenhouse or even a polyhouse will be the best option. The ROI will depend on the CEA you choose, as some have high costs, and returns may take time. Farm Size and Future Expansion Plans If you prefer flexible options, a polyhouse could be a suitable choice. However, if it is on a large scale, a greenhouse will be more effective. Conclusion The cost and performance of CEAs will vary depending on their type and supplier. You can select a low-cost solution, but the results will not be favorable. If you go with a high-cost solution, the results will be high because the farming conditions will be met. It all depends on the structure you go with. There is a table and a comparison that will help you make better decisions. Frequently Asked Questions 1. Can shade nets withstand heavy rain? No, they are not capable of dealing with harsh weather conditions. 2. Is a polyhouse better than a greenhouse? In most cases, a greenhouse is preferable to a polyhouse, especially if you are working within a tight budget. If the climate is mild, you can choose a polyhouse. 3. What crops thrive in greenhouses? Lettuce, chilies, spinach, leafy greens, cabbage, tomatoes, and cucumbers can thrive in greenhouses. Even exotic plants and certain types of vegetables can grow in greenhouses. 4. How do we maintain polyhouse films? Use mild detergent or cleaning soap to remove dirt from poly house films. Also, avoid excessive stretching or pressure when installing and cleaning them. Prevent sharp objects and plants from making contact with PE films. Also, use UV-resistant PE films for the polyhouse.

Welcome Our Company

Shandong Tongguang Chemical Fiber Rope Net Co., Ltd

Tongguang rope net is a production of hardware labor insurance, outdoor mountaineering, fire escape products company, the company perennial production of various types of products, can also be customized, the current company staff of more than 50 people, the company is located in the beautiful hometown of Binzhou City, welcome friends from all walks of life to talk about cooperation.